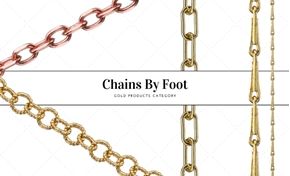

- Chains

-

JEWELRY GOLD FINDINGS

- RING MOUNTINGS

- BRACELETS

- EARRINGS

-

WIRES SHEETS SOLDERING AND BEZEL STAMPING

-

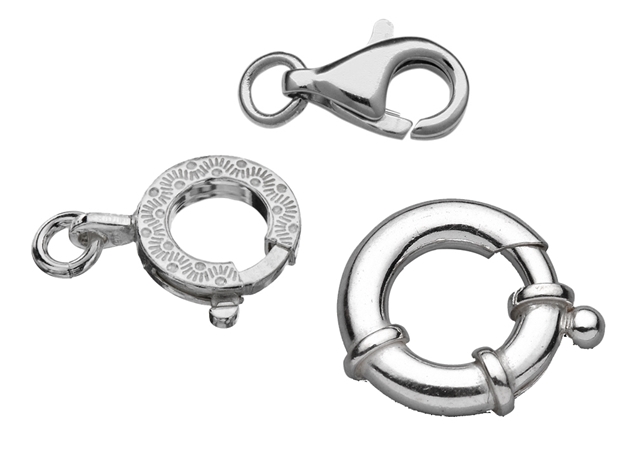

SILVER FINDINGS

- PLATINUM

- STULLER

- Sale

- New

About us

"Pasternak Findings" (Pasternak Recovery of metals ltd.) is a private owned company, held by Zeev & Martine Pasternak and is in the Jewelry Supply business for more than 20 years.

Pasternak Findings is a wholw sale one-stop-shop for diamond dealers, goldsmiths,

designers, creators, small manufacturers and students.

We offer you

- Unique jewelry findings

- Customized jewelry making supplies (Precious metal wires and sheets in non-standard sizes and karat)

- Gold findings and gold supply: 9K, 14K, 18K, 22 & 24K (fine gold)

- Silver findings and supply: 925 sterling silver, 999 fine silver

- Superior quality jewelry findings and materials - guaranteed

- Finished Jewelry

- Fast shipping & quick delivery

- No hassle returns

BEST QUALITY AND CUSTOMER SERVICE

The initial activity of the company was supplying refining services to the jewelry industry, together with production and sale of related materials to the jewelry industry, like wide range of gold and silver wires and plates, soldering wires and plates, decorative strips in all sizes, colors and karats, and soldering pastes.

Based on its relative advantage in customized production (special sizes, colors etc.) and the important knowledge of the jewelry industry, the company has implied the concept of "one-stop-shop", for the best benefits of Diamond dealers ,goldsmiths, designers, creators, small manufacturers and students, on which it offers its clients the whole range of findings, materials, and related items for the creation of fine jewelry.

We wish you a pleasant visit in our site.

Please contact us for any professional assistance you may need.

Your comments would be very much appreciated.

Powered by nopCommerce

Copyright © 2025 pasternakfindings. All rights reserved.

Pasternak Findings doesn't settle for less than the highest quality of jewelry findings, silver, and gold raw materials, or any other jewelry making supplies. Get the finest sheets at your desired hardness and be sure to enjoy your work.

Got ANY problem at all? our team is here to help and support you before and after your purchase. And, in the unlikely event that you wish to return part of or all your order, we don't ask questions or charge any restocking fees. That's how sure we are of our products! CONTACT US for any question! Harakon 11 Str. Diamond Stock Exchange District, P.O.BOX 3398 Ramat-Gan 5252238, Israel , Phone: +972-3-5256047, Fax : +972-3-5256075 ,

E-mail: Info@pasternakfindings.com